- Stage of development

-

Compound validation in a laboratory setting. Physicochemical and rheological characterization performed.

- Intellectual property

-

Priority patent application filed

- Intended collaboration

-

Licensing and/or co-development

- Contact

-

Pablo López FernándezVice-presidency for Innovation and Transferpablo.lopez@eez.csic.escomercializacion@csic.es

- Reference

-

CSIC/PL/002

Additional information

#Biotechnology

#Biomaterial

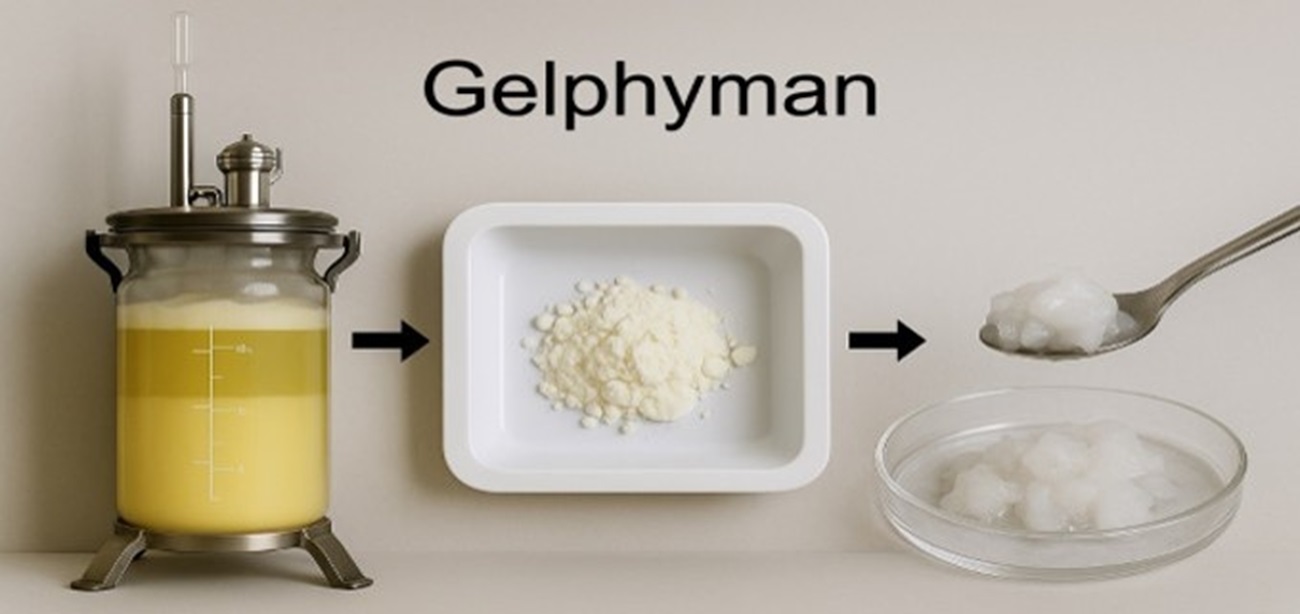

Gelphyman: Gelling polysaccharide for the production of phermo-adaptive hydrogels

New bacterial polysaccharide with the ability to form reversible thermo-adaptive hydrogels. Its thermo-responsive properties make this polymer an effective tool for the development of innovative solutions in medicine, food, biotechnology and other fields.

- Market need

-

The search for and production of new biomaterials that reduce dependence on petroleum-derived products is essential. In this context, bacterial biopolymers are generating growing industrial interest due to their purity, unique physicochemical properties, and the relative ease with which they can be obtained compared to other raw materials. Moreover, the high metabolic versatility of bacteria allows for their production from various industrial by-products, fostering the circular economy. Being biodegradable, biocompatible, and naturally derived materials, they contribute to addressing mayor social and industrial challenges, such as the need to generate sustainable alternatives to synthetic polymers.

- Proposed solution

-

Bacterial polysaccharide (Gelphyman) with thermoreversible gelling capability. The hydrogel formed by this polymer exhibits a gelation transition temperature close to physiological levels (36 °C) without the need for external catalysts, making it particularly attractive for biomedical and tissue engineering applications.

Replacing synthetic polymers with biodegradable alternatives such as Gelphyman can reduce the use of chemical agents and energy in the manufacturing processes of medical and cosmetic products, thereby increasing safety and reducing microplastic pollution.

- Competitive advantages

-

- Natural polymer, which provides greater biocompatibility and biodegradability than synthetic polymers and has high scalability potential for its production.

- Ability to gel on its own solely through temperature changes, without the need for added crosslinking agents.

- Potential applications include: tissue engineering and cell culture, injectable medical devices, biosensor systems and thermal actuators o smart materials. for cosmetics and drug delivery, among others.